Recently, an evaluation team of 7 experts assessed the results of Dalian Storage and Transportation Company's 2023 "Human-Machine Isolation, Machine Replacement, Lights-Out Factory" project.

After listening to reports on achievements, conducting on-site inspections, reviewing outcome demonstrations, and examining documentation, the expert team unanimously agreed that Dalian Storage and Transportation Company's project met the evaluation standards and achieved the expected results, approving it to pass the outcome assessment. This marks the successful completion of all construction objectives for the "Human-Machine Isolation, Machine Replacement, Lights-Out Factory" project.

Upon initiating the project, Dalian Storage and Transportation Company promptly organized an expert team to comprehensively analyze and identify risks in tank farm operations, precisely pinpointing hazardous workplaces, hazardous job positions, and personnel involved in dangerous tasks. Simultaneously, the company actively sought resources from multiple parties to discuss construction plans, gaining insights into the industry's current "Human-Machine Isolation, Machine Replacement, Lights-Out Factory" practices. Multiple expert reviews were conducted to finalize the construction plan.

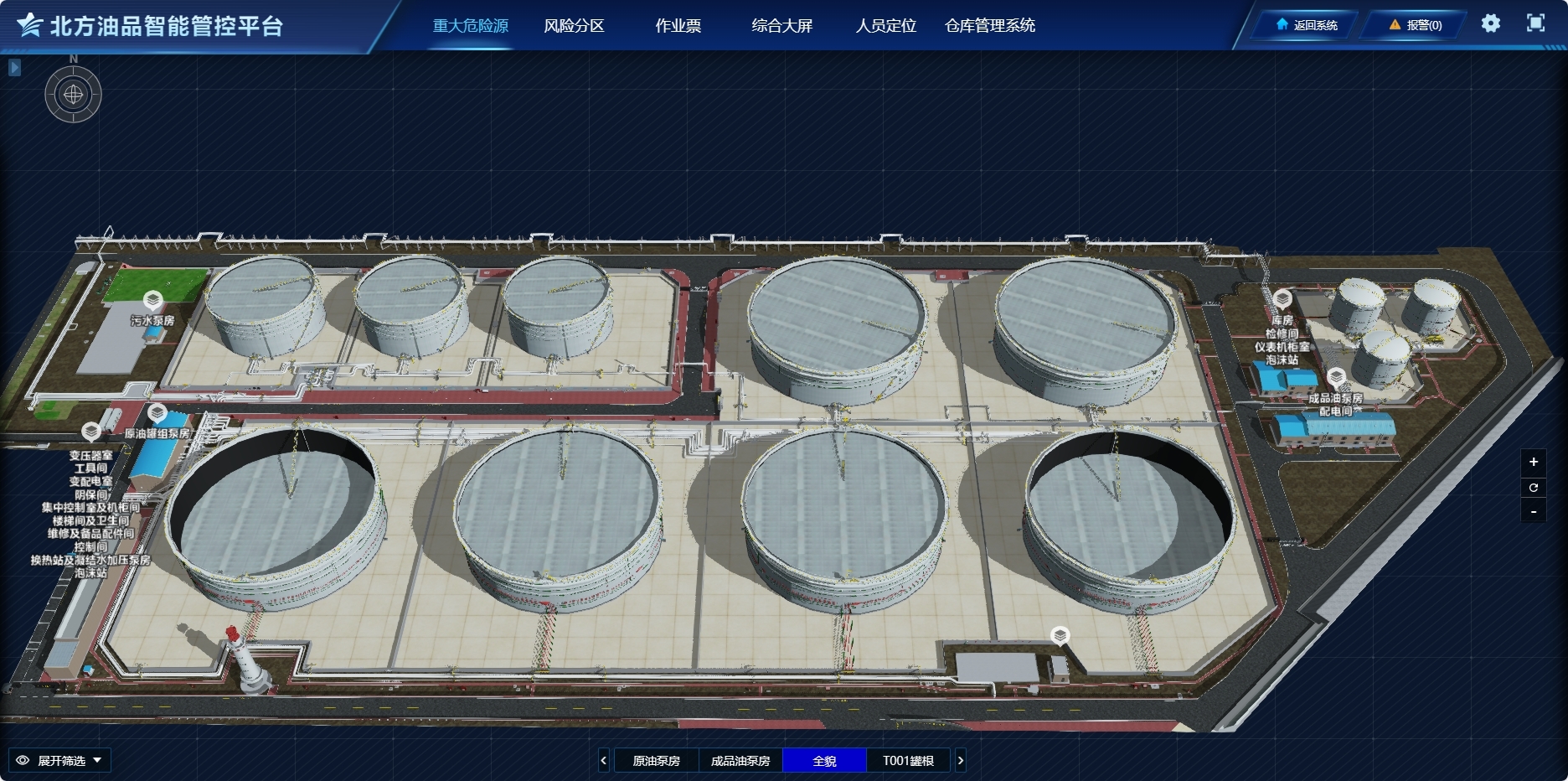

With a systematic mindset, Dalian Storage and Transportation Company proposes an integrated multi-system solution centered on a "Process Remote Control System", supported by an "Automatic Fire Control System" and a "Smart Safety Risk Management Platform". The "Process Remote Control System", featured with remote valve operation, remote start/stop and remote monitoring capabilities, enables remote control and data monitoring of production equipment, achieving the "Human-Machine Isolation" objective. The "Automatic Fire Control System", comprising fire detectors, infrared thermal imaging cameras, and automatic sprinkler and extinguishing equipment, enables automatic fire monitoring, warning and combatting, achieving the "Machine Replacement" objective. The "Smart Safety Risk Management Platform", integrating video surveillance, AI analysis, lightning warning and predictive maintenance systems for pumps, enables digitalized production, safety management and personnel management. The integration of the three systems enhances the inherent safety level of the tank farm, and achieves the "Lights-Out Factory" objective.

The "Human-Machine Isolation, Machine Replacement, Lights-Out Factory" adopts an endpoint security management system to keep the tank farm's control system from cybersecurity threats, fundamentally ensuring the safe storage of oil products.